Can An Automatic Stripping Machine Handle Different Cable Sizes Accurately?

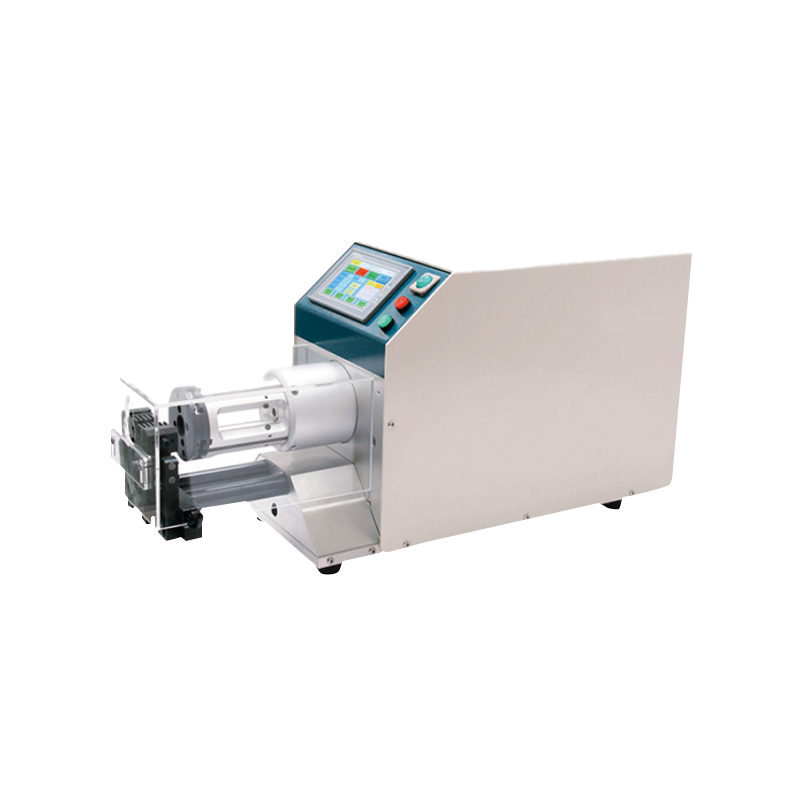

In cable production, precision and consistency are essential for maintaining quality and reducing waste. An Automatic Stripping Machine offers a practical solution by accurately removing insulation from coaxial and other cables. Its combination of great mechanics and user-friendly controls ensures professional results across various industrial applications.

Enhancing Efficiency and Speed

An Automatic Stripping Machine is designed for high-volume production, allowing operators to process large quantities of cables quickly. Automated controls and precision cutting mechanisms reduce human intervention, which decreases the likelihood of errors while maintaining consistent results. Industries such as telecommunications, automotive, and electronics rely on these machines to meet tight production schedules and maintain quality standards.

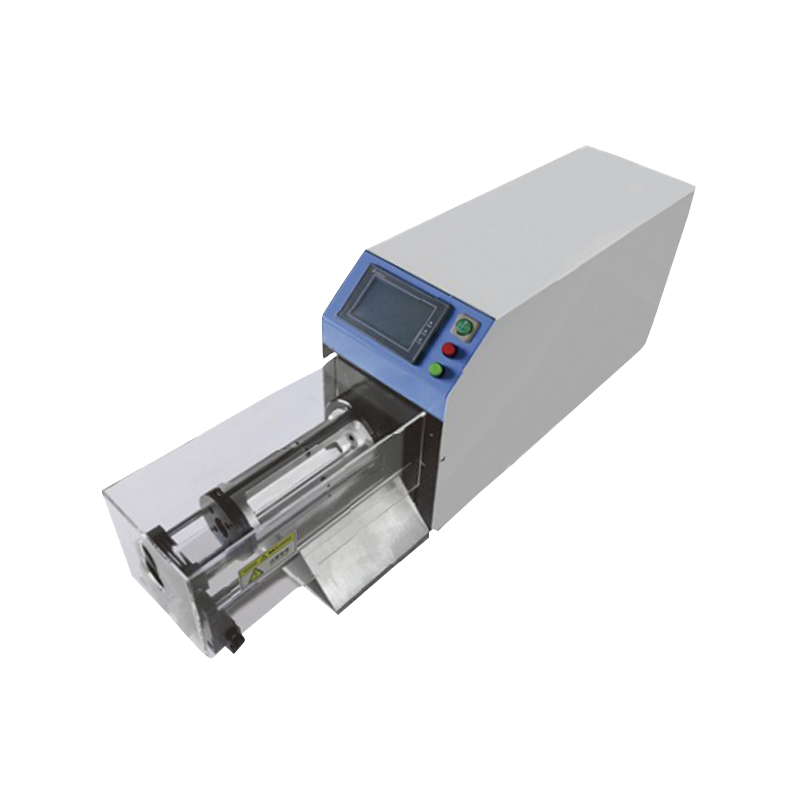

High-speed operations do not compromise accuracy. With adjustable stripping parameters, the machine can handle different cable diameters and insulation types, ensuring that the internal conductors remain intact and signal integrity is preserved.

Choosing the Right Automatic Stripping Machine Factory

Partnering with a reputable Automatic Stripping Machine Factory is crucial for achieving reliable performance and long-term value. Key considerations include:

- Customization Options: Machines can be tailored to specific cable types and production requirements.

- Component Quality: Durable cutting and stripping parts reduce maintenance and downtime.

- Technical Support: Comprehensive service ensures machines stay operational and optimized.

A trusted manufacturer helps guarantee that your Automatic Stripping Machine delivers precise results while minimizing operational disruptions.

Applications Across Industries

An Automatic Stripping Machine is versatile, making it suitable for diverse industrial sectors:

- Telecommunications: Ensuring accurate stripping for network cables and connectors.

- Automotive: Processing wiring harnesses efficiently for assembly lines.

- Aerospace: Maintaining conductor integrity for high-performance cabling.

Electronics Manufacturing: Preparing cables for assembly without damaging insulation or shielding.

This adaptability allows manufacturers to meet different project requirements using a single, reliable machine.

Reducing Errors and Maintenance

Operator errors and improper handling are common issues in manual stripping processes. Electric and pneumatic automated stripping machines mitigate these problems by controlling the cutting depth, stripping length, and alignment with precision. Proper maintenance, such as regular cleaning, lubrication, and inspection, helps extend the machine's operational life.

Using parts and dies recommended by the Automatic Stripping Machine Factory also ensures longevity and consistent output. By minimizing rework and scrap, manufacturers save time, labor, and material costs over the production lifecycle.

Optimizing Performance and Integration

Modern Automatic Stripping Machines focus on ease of use and integration:

- User-Friendly Interface: Simplifies setup and operation, reducing training requirements.

- Versatility: Accommodates multiple cable sizes and types.

- Automation Ready: Can be integrated into production lines for streamlined workflow.

- Safety Features: Includes emergency stops, guards, and instructions to protect operators.

Choosing a reliable Automatic Stripping Machine Factory often comes with technical guidance on configuring machines for specific production needs, which helps optimize efficiency and reliability.

Investing in an Automatic Stripping Machine from a skilled Automatic Stripping Machine Factory offers practical benefits: higher efficiency, consistent stripping quality, and reduced errors. Proper selection, maintenance, and integration into production processes ensure that the machine supports a range of industrial applications while lowering operational risks and material waste.

With precision, automation, and flexibility, an Automatic Stripping Machine becomes a strategic asset in modern cable processing, meeting industry demands without sacrificing quality or productivity.

EN

EN  English

English русский

русский Español

Español عربى

عربى