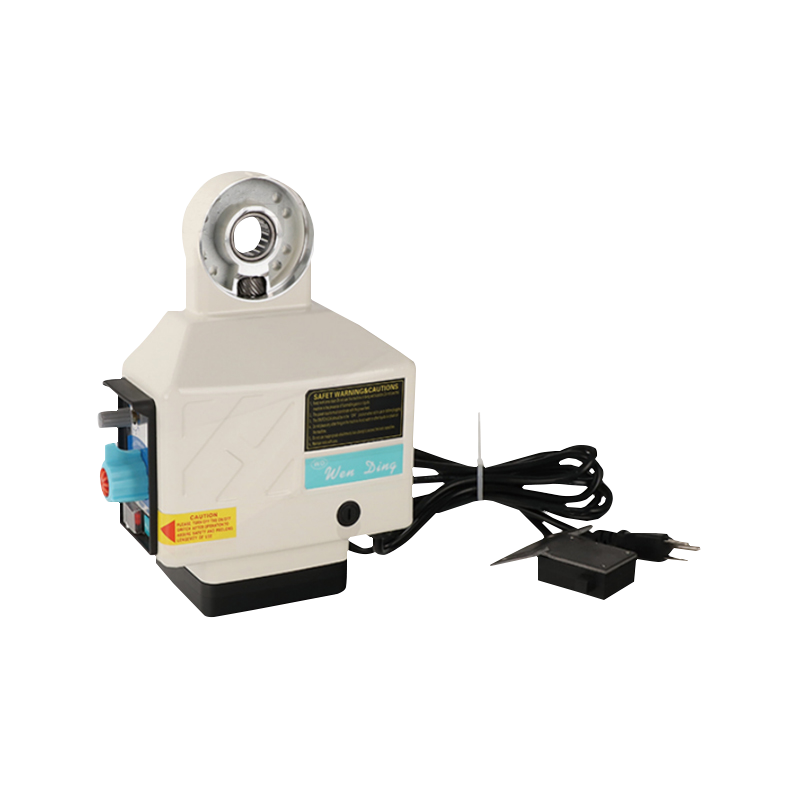

How To Boost Precision In Parts With An Axis Milling Machine?

Producing highly precise parts is a common goal in manufacturing, whether for the aerospace, medical, or automotive sectors. One of the impactful factors in achieving this is the effective use of an Axis Milling Machine. But how exactly can you enhance precision using this technology? The answer often lies not only in the machine itself but also in the tools it uses and where those tools come from—a reliable Axis Milling Machine Factory.

The Role of High-Tools from a Specialist Axis Milling Machine Factory

At the heart of any successful milling operation are the tools. Not all cutting tools are created equal. Tools produced by a professional Axis Milling Machine Factory are typically manufactured under strict controls. These factories employ every step, meaning each tool is designed to maintain accuracy over its entire lifespan. Using substandard tools can cause deflection, wear, and out-of-tolerance parts.

Choosing the Right Tool for Your Axis Milling Machine

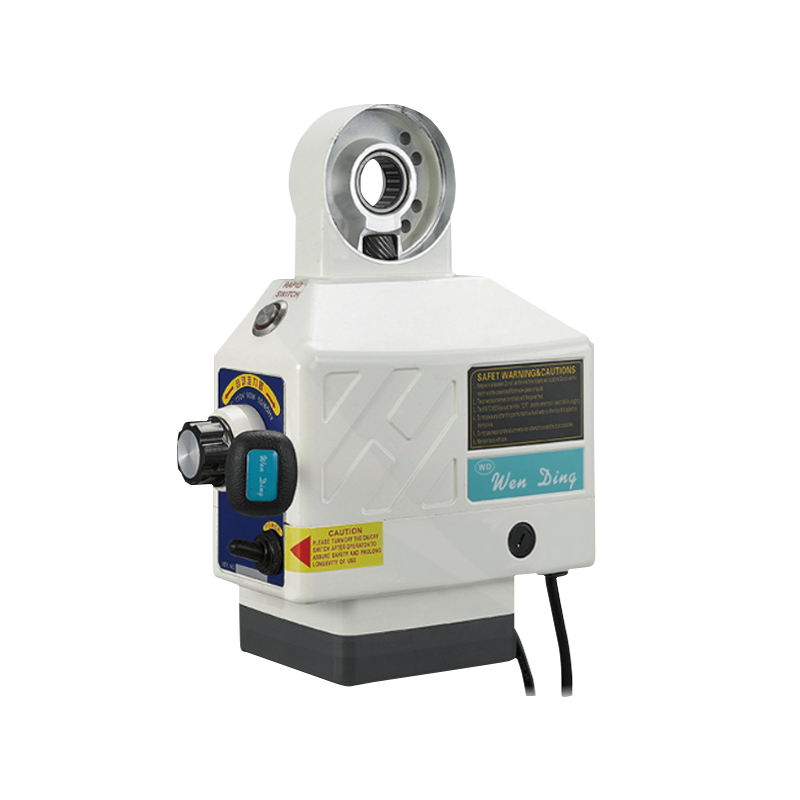

An Axis Milling Machine is a versatile system, but its performance depends heavily on selecting the correct cutter. The variety available—from end mills to face mills and slot drills—allows manufacturers to match the tool to the specific material and cut type. For instance, a roughing end mill can quickly remove material, while a fine-finishing tool is engineered for tight tolerances and smooth surfaces. Using a specialized tool for its intended application prevents unnecessary vibration and tool pressure, two common enemies of precision. A knowledgeable Axis Milling Machine Factory can provide valuable guidance in selecting the ideal toolset for your particular applications, be it machining engine components or medical devices.

The Impact of Tool Maintenance and Setup

Even the tool can underperform if not handled correctly. The design of tools, including aspects like ergonomic mounting features, helps ensure they are installed in the Axis Milling Machine correctly and securely. A poorly seated tool will certainly cause runout, reducing accuracy and potentially damaging the part. Furthermore, monitoring tool wear and adhering to a structured maintenance schedule helps sustain performance.

Balancing, Feed, and Material Considerations

Another factor influencing precision is how the Axis Milling Machine is operated. The properties of the workpiece material greatly affect the machining strategy. Softer materials like aluminum allow for different parameters than harder alloys. Finding the right balance between cutting, feed rate, and depth of cut is crucial. An overly aggressive cut can generate heat and cause tool deflection, while too conservative an approach may not allow the tool to cut properly, causing poor surface finish. The built-in versatility of a modern Axis Milling Machine, when paired with appropriate tooling, offers the flexibility needed to adapt to these different materials—from automotive parts to complex aerospace components.

Customization and Technical Support: Working with Your Factory

Standard tools are not quite enough. Unique projects may require custom solutions. This is where the support of your Axis Milling Machine Factory becomes invaluable. Many factories provide customization options, tailoring tools for specific, unusual materials or complex geometries. This close collaboration can solve unique production challenges, enhancing the capability of your Axis Milling Machine. Additionally, strong after-sales support and access to technical expertise can help troubleshoot precision issues quickly, reducing downtime and maintaining the part.

Boosting precision with an Axis Milling Machine is a multi-faceted effort. It combines the inherent accuracy of the machine with the selection of the tools, intelligent operation, and consistent maintenance. Partnering with a proficient Axis Milling Machine Factory that provides high-performance, durable, and application-specific tools gives manufacturers a clear path to achieving higher precision and better parts across all their projects.

EN

EN  English

English русский

русский Español

Español عربى

عربى