Is An Automatic Stripping Machine Energy-Efficient?

In an era where industries are increasingly focused on reducing operational costs and environmental impact, the energy efficiency of machinery has become a crucial consideration. When it comes to wire processing, many wonder: Is an Automatic Stripping Machine designed with energy savings in mind? The answer leans positively, but it helps to understand how and why.

An Automatic Stripping Machine is engineered to perform wire stripping tasks with human intervention. Unlike older, continuously running machines, modern versions often incorporate smart power management. They tend to draw electricity mainly during active processing cycles, reducing idle consumption. This on-demand operation already gives them an efficiency edge over traditional equipment.

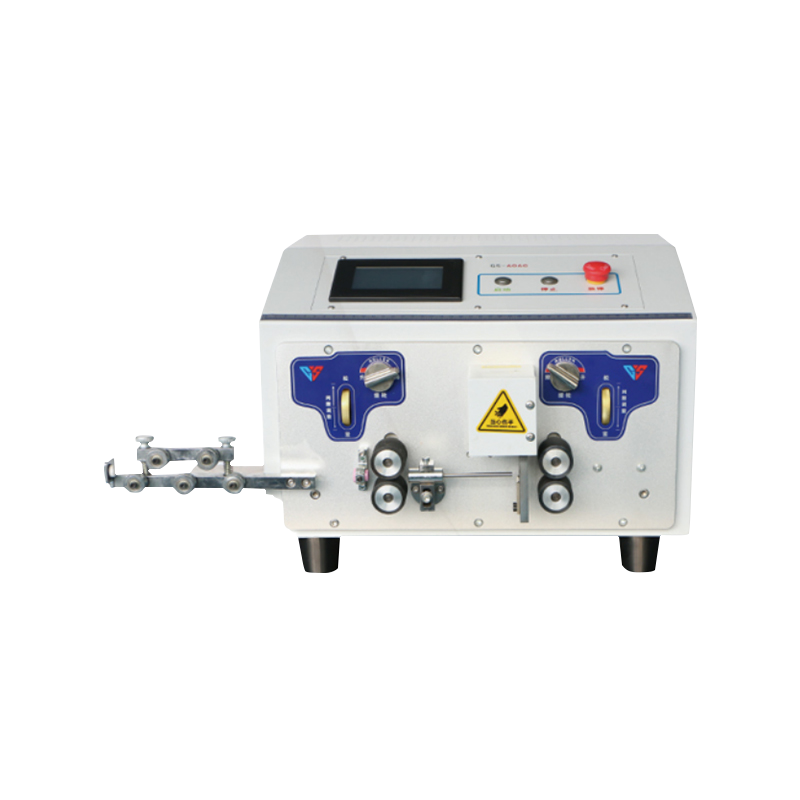

The design and components play a significant role. Reputable Automatic Stripping Machine Factory providers prioritize the use of efficient electric motors and controllers. Many models are equipped with servo motors, which consume power more selectively compared to constant-running hydraulic systems or older motor types. This approach not only supports precision but also lowers overall energy use.

Another aspect is the reduction in wasted material and rework. Because an Automatic Stripping Machine typically offers high accuracy in stripping length and depth, it may encounter errors that might require re-processing the same wire. Less reprocessing means less energy consumed per usable product, enhancing overall efficiency.

It's also worth considering the scale of operation. For businesses processing large volumes of wire, using an Automatic Stripping Machine can cause noticeable energy savings compared to manual methods or multiple standalone tools. Automation streamlines the workflow, often completing tasks faster and with a single power source.

When selecting a machine, the choice of Automatic Stripping Machine Factory can make a difference. Established manufacturers invest in research to improve the energy profiles of their products. They may integrate power-saving features such as automatic shutdown during prolonged inactivity or low-power standby modes. If energy efficiency is a priority, you can check out the technical specifications provided by Automatic Wire Stripping Machine Factory.

Maintenance also influences energy consumption. A well-maintained Automatic Stripping Machine operates smoothly, avoiding power spikes or inefficiencies caused by wear and tear. Regular cleaning and parts inspection will help maintain good performance. Reputable Automatic Stripping Machine Factory units often include guidance on upkeep for long-term efficiency.

From a broader perspective, using an Automatic Stripping Machine can contribute to a facility's sustainability goals. Lower energy usage per unit produced is a step toward reducing the carbon footprint of manufacturing or processing operations. This can be particularly important for companies seeking green certifications or aiming to meet corporate environmental targets.

Of course, actual energy consumption depends on factors like machine model, usage intensity, and types of wire being processed. It's always helpful to request energy consumption data from the Automatic Stripping Machine Factory or look for efficiency ratings when comparing options.

In summary, modern Automatic Stripping Machine systems are generally designed with energy consciousness. While not entirely free of power requirements, their intelligent operation and precision help keep energy use manageable and cost-effective. For businesses evaluating such equipment, reviewing the engineering behind the machine and choosing a reliable Automatic Stripping Machine Factory can help you get a solution that balances performance with efficiency.

EN

EN  English

English русский

русский Español

Español عربى

عربى