The Rise of Vertical Electric Stripping Machines

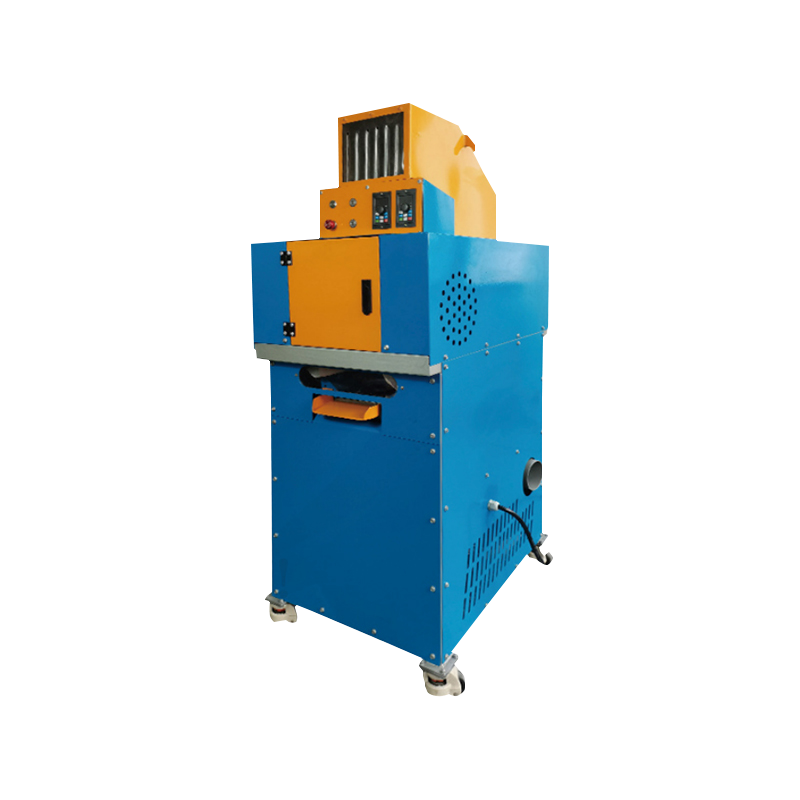

In the ever-evolving landscape of industrial manufacturing, the quest for space efficiency has led to a paradigm shift from horizontal to vertical equipment design. One such innovative solution is the vertical electric stripping machine, a technological leap that has significantly impacted the way line bundle processing workshops are organized and operated.

The traditional horizontal stripping machines, once the backbone of many production lines, have been replaced by their vertical counterparts, offering a new dimension in flexibility and efficiency. The vertical electric stripping machine, with its upright design, has become a game-changer in the wire and cable processing industry. This shift from horizontal to vertical not only saves floor space but also allows for a more streamlined workflow, enhancing the overall productivity of the workshop.

The vertical electric stripping machine's compact footprint is a boon for businesses operating in constrained spaces. By utilizing vertical space, these machines free up valuable floor area, which can be allocated to other critical production processes or for storage purposes. This innovation in machinery layout has led to a more organized and clutter-free workshop environment, contributing to improved safety standards and worker comfort.

Moreover, the vertical electric stripping machine's design allows for easier integration into automated production lines. Its vertical orientation aligns seamlessly with the upward and downward motion of automated systems, reducing the need for additional conveyors or complex machinery to manage the transition of materials. This integration capability has been a key factor in the adoption of these machines in modern, high-tech production facilities.

The flexibility in workshop layout that the vertical electric stripping machine offers is not just limited to space-saving. It also enables manufacturers to reconfigure their production lines more swiftly in response to changing market demands. With the ability to move these machines with relative ease, companies can adapt to new product lines or adjust to seasonal fluctuations without significant capital outlay on new equipment.

In terms of maintenance and operational efficiency, the vertical electric stripping machine has proven to be more accessible. Technicians can perform routine checks and maintenance more conveniently, thanks to the machine's upright structure. This ease of access reduces downtime and ensures that the machine remains in working condition, contributing to the reliability and consistency of the stripping process.

The vertical electric stripping machine's impact on line bundle processing is not just about physical space. It has also led to a rethinking of process flows within the workshop. By elevating the stripping process, these machines have encouraged a more logical and efficient sequence of operations, where stripped materials can be directly fed into subsequent processes without the need for additional handling or transfer.

As companies continue to seek ways to maximize their operational efficiency, the vertical electric stripping machine stands out as a practical and effective solution. Its ability to save space, streamline processes, and enhance flexibility has made it an essential piece of equipment in the modern line bundle processing workshop.

In conclusion, the vertical electric stripping machine represents a significant advancement in industrial equipment design. Its vertical structure has not only improved space efficiency but also enhanced the flexibility of workshop layouts. As more manufacturers recognize the benefits of this innovation, it is likely that the vertical electric stripping machine will become a standard feature in wire and cable processing facilities worldwide. The transition from horizontal to vertical is not just a change in orientation; it is a revolution in how we approach industrial production, one that promises to deliver greater efficiency and adaptability for the future.

EN

EN  English

English русский

русский Español

Español عربى

عربى