The Versatility of Multi Hole Wire Stripping Machine

In the ever-evolving world of electronics and electrical engineering, the demand for precision and efficiency in wire processing has never been higher. The Multi Hole Wire Stripping Machine stands out as a solution that addresses these needs with its remarkable versatility. This innovative tool is designed to handle a variety of wire diameters and materials, making it an indispensable asset in any workshop or manufacturing setting.

The Multi Hole Wire Stripping Machine's versatility is its compelling feature. It is capable of stripping wires of various diameters and materials with equal ease. This adaptability increases the machine's applicability and flexibility, allowing it to be used in a wide range of applications from electronics manufacturing to automotive wiring harnesses.

Versatility in Handling Different Wire Diameters

One of the key strengths of the Multi Hole Wire Stripping Machine is its ability to accommodate wires of different diameters. This feature is particularly beneficial for industries that work with multiple wire sizes on a regular basis. By having a single machine that can handle a broad range of diameters, businesses can streamline their operations and reduce the need for multiple stripping tools. The Multi Hole Wire Stripping Machine's design ensures that it can efficiently strip wires from thin, delicate strands to thicker, more robust cables without compromising on quality or precision.

Adapting to Different Line Materials

The Multi Hole Wire Stripping Machine is not limited to just one type of wire material. It can handle a variety of materials, including but not limited to, copper, aluminum, and even some insulated wires. This adaptability ensures that the machine remains relevant and useful regardless of the specific materials that a business might be working with. The ability to strip different materials without the need for additional tools or adjustments is a testament to the Multi Hole Wire Stripping Machine's versatility.

Support for Diverse Wire Shapes and Sizes

The Multi Hole Wire Stripping Machine is also designed to support different shapes and sizes of wire, such as round and flat wires. This feature is crucial for industries that require precision in their wire processing, such as in the aerospace or medical device manufacturing sectors. By being able to accommodate these diverse shapes, the Multi Hole Wire Stripping Machine ensures that manufacturers can achieve the exact specifications they need for their projects without the hassle of switching between different machines or tools.

Efficiency and Cost-Savings

The efficiency of the Multi Hole Wire Stripping Machine cannot be overstated. By being able to strip wires of various diameters and materials with a single machine, businesses can save significantly on both time and costs. There is no need to purchase and maintain multiple stripping machines, which can be a substantial expense. Additionally, the time saved by not having to switch between machines can be redirected towards other tasks, increasing overall productivity.

Precision and Quality

Precision is at the heart of the Multi Hole Wire Stripping Machine's design. Each hole in the machine is carefully engineered to provide a clean and precise strip every time. This precision is crucial for maintaining the integrity of the wire and ensuring that it can perform its intended function without any issues. The quality of the stripped wire is consistent, regardless of the diameter or material, which is a significant advantage for businesses that require high standards in their wire processing.

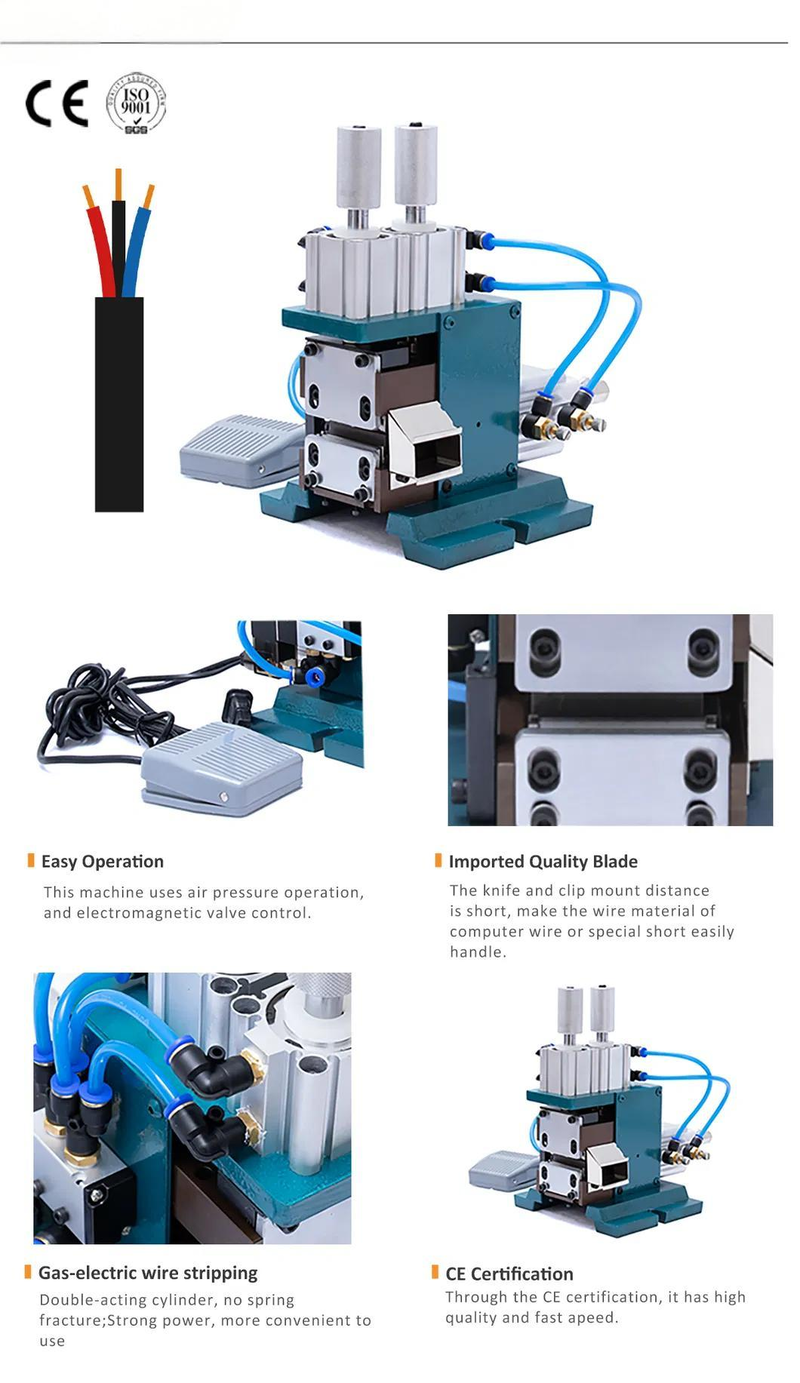

Simplicity and Ease of Use

The Multi Hole Wire Stripping Machine is designed with user-friendliness in mind. Its simple operation allows even those without extensive experience in wire stripping to use it effectively. This ease of use is a significant advantage for businesses as it reduces the need for extensive training, allowing employees to focus on other tasks. The simplicity of the Multi Hole Wire Stripping Machine also reduces the likelihood of user error, ensuring that the wire stripping process is as efficient and accurate as possible.

The Multi Hole Wire Stripping Machine is a testament to the power of versatility in the world of wire processing. Its ability to handle a variety of wire diameters, materials, and shapes makes it an invaluable tool for any industry that requires precision and efficiency in their wire processing. The Multi Hole Wire Stripping Machine not only saves time and costs but also ensures that the quality of the stripped wire is consistently high. As industries continue to evolve and the demand for high-quality wire processing increases, the Multi Hole Wire Stripping Machine stands ready to meet these challenges with its unparalleled versatility.

In conclusion, the Multi Hole Wire Stripping Machine is more than just a machine; it is a solution that adapts to the ever-changing needs of wire processing. Its versatility is not just a selling point; it is a promise of reliability, efficiency, and precision that businesses can count on. The Multi Hole Wire Stripping Machine is truly a game changer in the field of wire stripping, and its impact will be felt for years to come.

EN

EN  English

English русский

русский Español

Español عربى

عربى