Troubleshooting Common Issues with Coaxial Semi-Automatic Stripping Machines

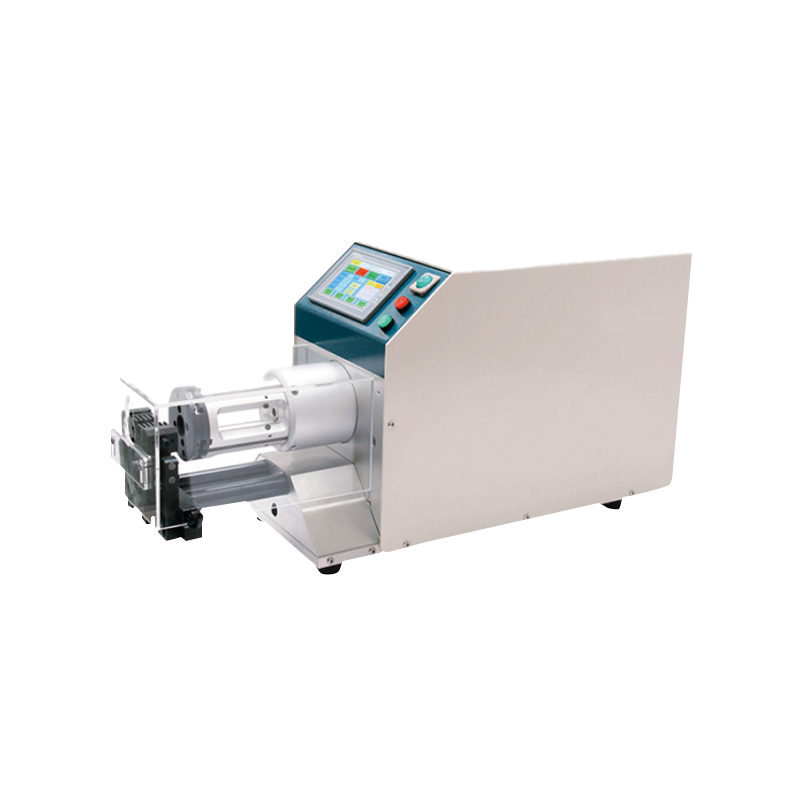

In the demanding world of cable preparation for telecommunications, broadcast, and high-frequency applications, the Coaxial Semi-Automatic Stripping Machine is an indispensable workhorse. These machines significantly boost productivity and consistency compared to manual stripping. However, like any precision tool, operators occasionally encounter performance hiccups. Understanding how to diagnose and resolve common problems is key to maintaining output and minimizing costly downtime. This guide focuses on practical troubleshooting for the ubiquitous Coaxial Semi-Automatic Stripping Machine.

1. Inconsistent Strip Length or Quality

Perhaps the frequent complaint is inconsistent strip length or ragged, uneven cuts. When facing this with your Coaxial Semi-Automatic Stripping Machine, start with the basics:

Cable Positioning: Ensure the cable end is firmly seated against the machine's stop block or sensor. Wear or misalignment here is directly related to length variations. Regularly inspect and clean the stop mechanism.

Blade Sharpness & Alignment: Dull or nicked blades are prime culprits. The precision blades in a Coaxial Semi-Automatic Stripping Machine require regular inspection and sharpening/replacement. Equally critical is verifying blade alignment according to the manufacturer's specifications; even slight deviations cause tearing or incomplete cuts. Recalibrate if necessary.

Clamping Force: Insufficient clamping allows the cable to move during the stripping cycle, ruining precision. Check clamp pressure settings and inspect clamp pads for wear or debris build-up. Conversely, excessive force can deform softer cables.

2. Difficulty with Jacket or Shielding Removal

Struggling to cleanly remove the outer jacket or, more critically, the shielding (braid or foil) without nicking the dielectric or center conductor signals an issue needing attention on your Coaxial Semi-Automatic Stripping Machine:

Depth Settings: Incorrect depth adjustment is the common cause. Refer to the cable manufacturer's specs and the machine's manual. Even minor adjustments can make a significant difference. Recalibrate depth settings meticulously when switching cable types.

Worn or Incorrect Blades: Specific blades are designed for specific materials (jacket vs. shield). Using a jacket blade on shielding, or vice versa, yields poor results. Ensure the correct blade set is installed for the material being stripped and that they are sharp. Worn blades require more force, increasing the risk of damaging underlying layers.

Blade Holder Tension: Improper tension in the blade holder mechanism can cause blades to deflect or vibrate during the cut, to inconsistent depth penetration and potential damage. Consult your Coaxial Semi-Automatic Stripping Machine manual for correct tensioning procedures.

3. Machine Jamming or Cable Slippage

A jammed Coaxial Semi-Automatic Stripping Machine halts production. Prevention and quick resolution are vital:

Debris Accumulation: Stripping generates plastic shavings and metal particles. Buildup inside the cutting head, clamps, or feed path is a major cause of jams. Implement a strict, frequent cleaning schedule as specified in the machine's maintenance guide.

Clamp Issues: Worn clamp pads lose grip, causing slippage. Inspect pads regularly and replace them when smooth or damaged. Also, verify the clamp mechanism is operating smoothly and generating adequate force without binding.

Misaligned Feed Path: If the cable isn't feeding straight into the cutting head, binding can occur. Check guide rollers, bushings, and the feed path alignment. Any obstruction or misalignment needs correction.

4. Inconsistent Performance After Cable Change

The versatility of a Coaxial Semi-Automatic Stripping Machine means frequent cable changes. Problems arising post-change usually point to setup:

Incomplete Reprogramming/Adjustment: Neglecting to fully adjust blade depths, strip lengths, clamp pressures, and potentially blade types when switching cable specs is a common oversight. Always follow the machine's procedure for cable changeover meticulously. Don't assume settings for one cable will work perfectly on another, even if similar.

Tooling Compatibility: Ensure the installed stripping blades and collets are actually compatible with the new cable's diameter and construction. Using incorrect tooling guarantees poor results and potential damage to the Coaxial Semi-Automatic Stripping Machine or the cable.

5. General Performance Degradation & Maintenance

Often, gradual declines in performance stem from lack of routine care:

Lubrication: Moving parts require proper lubrication as per the manufacturer's schedule. Use only recommended lubricants. Over-lubrication can attract debris.

Component Wear: Bearings, slides, springs, and sensors wear over time. Schedule periodic inspections based on usage. Proactive replacement of worn parts prevents unexpected failures.

Sensor Malfunction: Position

sensors (if equipped) can get dirty or fail. Clean optical sensors carefully; check mechanical sensor operation. Faulty sensors to inconsistent cycle starts or stops.

Power & Pneumatics: Ensure a stable electrical supply. For pneumatic machines, check air pressure consistency, filter regularly, and ensure lines/dryers are functioning to prevent moisture issues affecting cylinders and valves.

The Coaxial Semi-Automatic Stripping Machine is a precision instrument demanding respect and regular maintenance. common issues—inconsistent stripping, jamming, and shielding problems—can be resolved through methodical troubleshooting focused on blade condition, calibration, clamping, cleanliness, and correct setup for the specific cable. Implementing a robust preventive maintenance schedule, keeping detailed logs, and ensuring operators are thoroughly trained on both operation and basic troubleshooting procedures for their Coaxial Semi-Automatic Stripping Machine are the investments for uptime, ensuring consistent, high-quality coaxial terminations, and protecting your valuable equipment for the long term. When in doubt, always consult the specific manual for your machine model.

EN

EN  English

English русский

русский Español

Español عربى

عربى