Why Automatic Stripping Machines Are Changing Wire Processing?

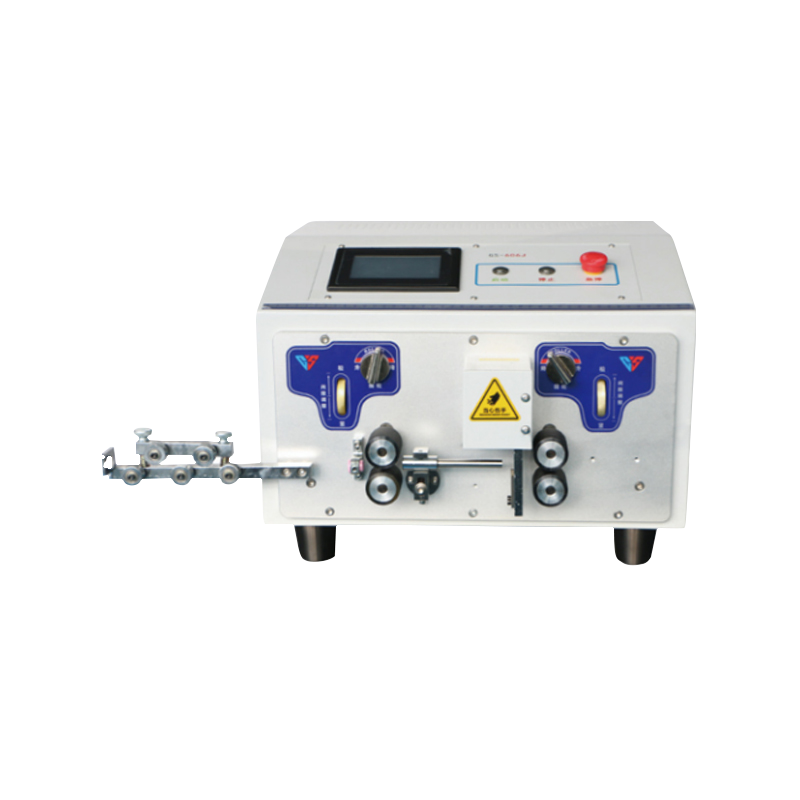

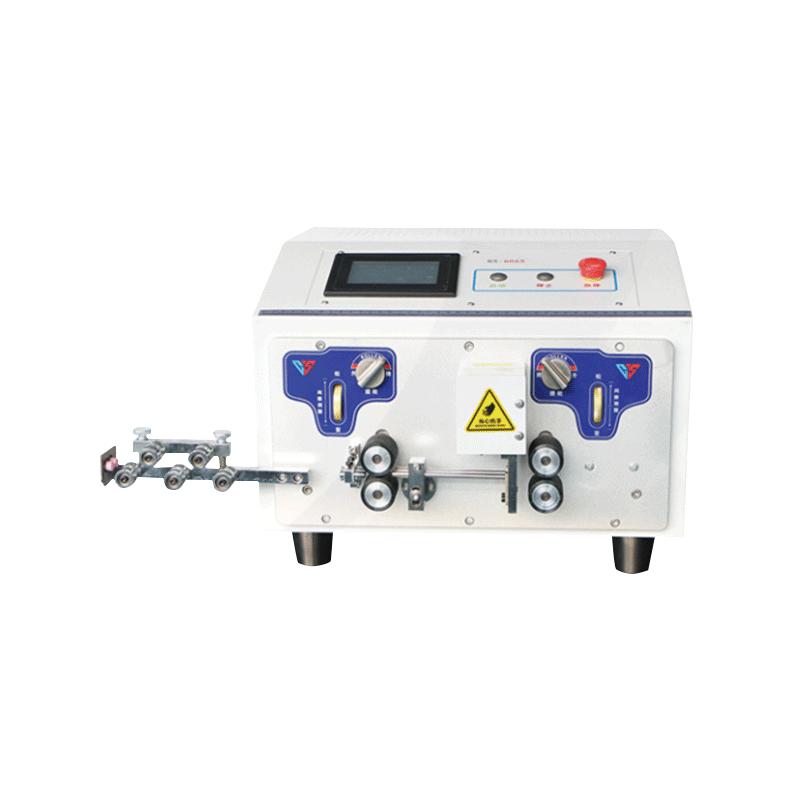

In the world of modern manufacturing, time, precision, and consistency matter more than ever. That's why many factories are turning to the Automatic Stripping Machine. It has quietly become one of those behind-the-scenes tools that keep production running smoothly-especially in industries where every millimeter and second counts. But what makes these machines so important, and what do Automatic Stripping Machine Manufacturers focus on when developing them? Let's look at what users usually wonder and what these machines actually deliver.

1.How does an Automatic Stripping Machine improve daily production?

When wire processing is done manually, every step takes time and invites inconsistency. An Automatic Stripping Machine handles these tasks in a steady rhythm-cutting, stripping, and preparing wires with precise measurements every single time. For factories dealing with large volumes of cables, this consistency reduces waste and keeps the assembly line moving without interruption. It's not only about speed, but also about predictability. You know what to expect from the early wire to the last.

2. Can one machine handle different types of wires?

This is one of the many common questions from buyers. The good news is that many machines from experienced Automatic Stripping Machine Manufacturers are built with flexibility in mind. They can process everything from delicate signal wires to heavy power cables. With adjustable settings and intelligent control systems, these machines adapt to different diameters and materials. That means one piece of equipment can serve multiple production lines, saving both floor space and maintenance time.

3. Is the operation complicated for workers?

People often imagine automated machines as complex or hard to control. In reality, modern Automatic Stripping Machine models are surprisingly user-friendly. many come with a digital interface where operators can set parameters such as length, stripping depth, and wire type in just a few taps. Training new staff becomes faster, and experienced operators appreciate the repeatable accuracy that manual stripping could never match. It's a mix of technology and simplicity that works well in busy factory environments.

4. What makes one manufacturer stand out from another?

Not all Automatic Stripping Machine Manufacturers build their machines the same way. Some focus on durability and reliability, using stronger materials and testing their equipment under long production cycles. Others prioritize energy efficiency or offer customization to match unique production needs. The good approach is to look for a manufacturer that understands both your product requirements and the challenges of your industry. For example, automotive, telecom, and medical device sectors each have different wire standards-so a machine that allows precise control makes a real difference.

Behind every cable, appliance, or circuit lies careful wire processing, and that's where the Automatic Stripping Machine quietly proves its worth. It's not just a tool-it's an investment in smoother workflows, better consistency, and fewer production headaches. As technology keeps improving, Automatic Stripping Machine Manufacturers continue to refine how these machines handle every wire, helping industries move faster and work smarter.

EN

EN  English

English русский

русский Español

Español عربى

عربى