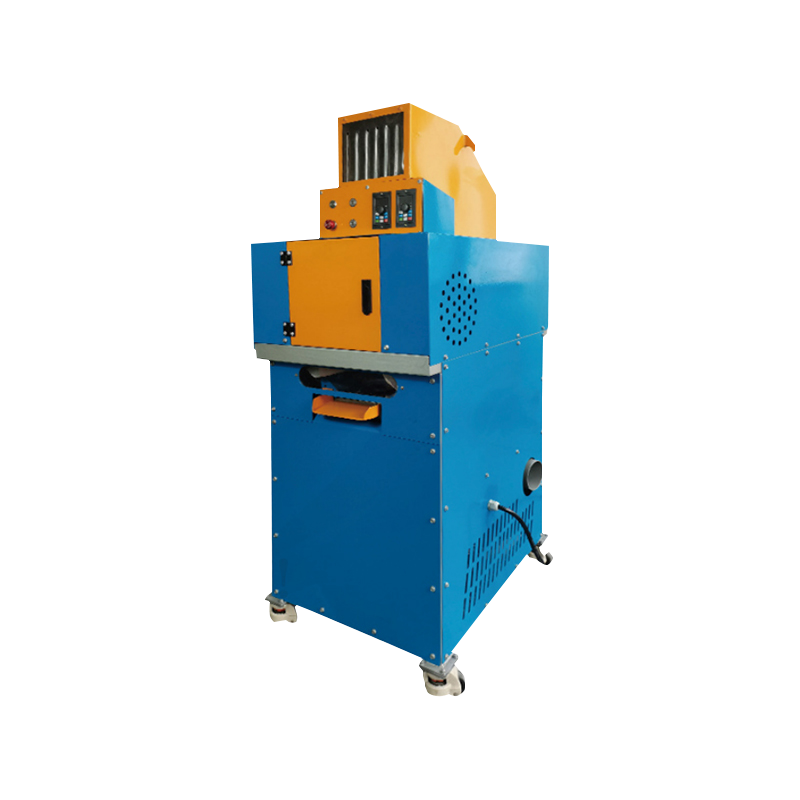

How To Choose A Vertical Electric Stripping Machine For Consistent Wire Results?

A key question from users is how stable cutting performance is maintained when dealing with mixed wire types. The vertical layout provides a steady feeding path, which helps keep the wire aligned during stripping. Combined with automated controls, the machine supports a consistent approach that reduces manual correction and keeps the stripped sections clean. This stability is valuable for factories handling frequent product changes or medium-to-large wire bundles.

Another common curiosity is whether a Vertical Electric Stripping Machine can handle wires with different insulation hardness. Manufacturers build these machines with adjustable blade positions and parameter settings, allowing users to adapt the stripping length and pressure according to the wire's outer layer. This functionality makes the machine suitable for projects found in electrical assembly, automotive harnesses, telecom cables, and recycling work. Instead of swapping equipment, operators can switch settings within minutes, which supports steady output in workshops with tight schedules.

A Vertical Electric Stripping Machine reduces repetitive manual tasks because it manages feeding, cutting, and stripping through programmed steps. It allows a single operator to supervise multiple runs rather than carry out hands-on stripping work all day. For factories aiming to reduce handling errors or stabilize productivity during peak orders, this structure becomes a practical choice. It also improves clarity in production planning since the machine can deliver consistent speed once parameters are set.

1. Cutting Accuracy and Wear Performance

Users look for high-precision cutting components that maintain their sharpness through long working cycles. Vertical Electric Stripping Machine Manufacturers often offer reinforced blades or modular blade blocks that can be replaced quickly. This directly affects long-term operating costs and helps maintain stable quality across large batches.

2. Machine Versatility for Different Wire Structures

Production lines seldom use one type of wire. A machine that allows quick adjustments for diameter, insulation type, and stripping length becomes valuable. Buyers also check if the machine supports both small wires and thicker cables, allowing more flexibility without investing in multiple units.

3. Ease of Operation and Interface Design

Factories appreciate equipment that shortens training time. A straightforward control panel and clear parameter settings reduce operator mistakes. Some models include memory storage for frequent wire types, allowing teams to switch jobs with minimal downtime. For teams with rotating operators, an intuitive workflow becomes a practical advantage.

4. Maintenance Steps and Component Accessibility

A good Vertical Electric Stripping Machine should allow quick access to moving parts for cleaning or lubrication. Stable construction and durable bearings also influence how smoothly the machine performs during long shifts. Buyers typically prefer models designed with front-open structures so operators do not need to dismantle the frame for routine work.

When comparing Vertical Electric Stripping Machine Manufacturers, buyers tend to focus on the supplier's experience in automated stripping systems, component durability, and available technical support. A reliable manufacturer provides guidance on matching the right model to wire specifications and production volume. This helps users avoid over-sizing or under-sizing the machine for their application.

A Vertical Electric Stripping Machine plays a direct role in improving productivity, reducing rework, and helping factories run more organized wire-processing lines. With a clear understanding of the machine's functions, adjustment options, and maintenance needs, buyers can select the model that fits their workflow and supports consistent performance.

EN

EN  English

English русский

русский Español

Español عربى

عربى