What Problems Can A Coaxial Semi-Automatic Stripping Machine Solve?

Coaxial cable processing often looks simple from the outside, but people working on the shop floor know how many issues hide inside the stripping step. Uneven jacket removal, damaged shielding, inconsistent strip length, and slow cycle time all affect downstream assembly. Manual stripping depends heavily on operator skill, which can vary from shift to shift. Fully automated systems may feel complex or inflexible for many production setups.

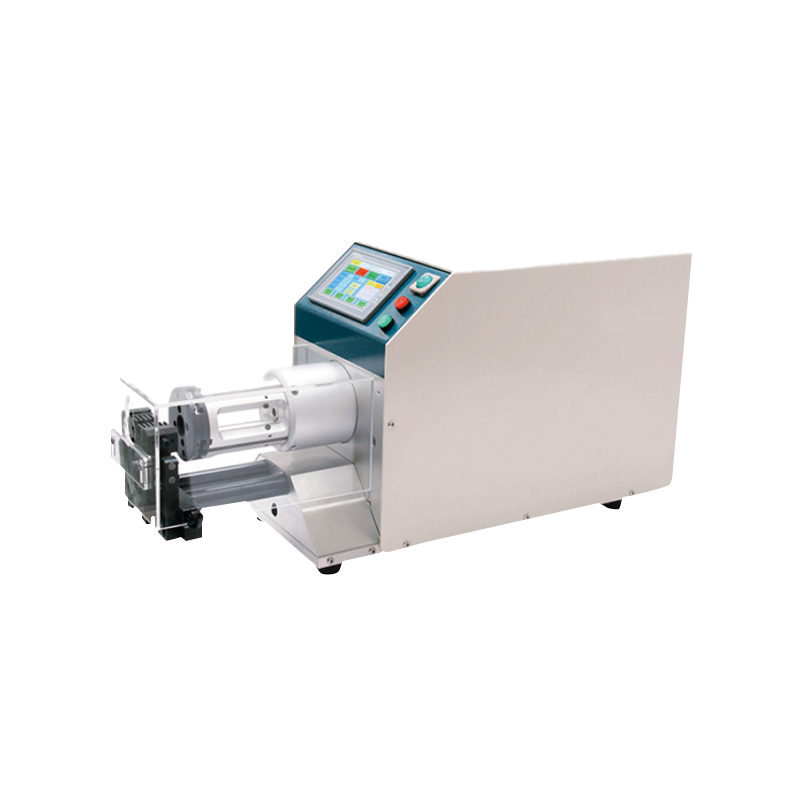

This is where a Coaxial Semi-Automatic Stripping Machine fits naturally into real production needs. It bridges the gap between hand tools and fully automated lines, offering stable performance while keeping the operation intuitive.

How Precision Matters for Signal-Sensitive Applications

Coaxial cables are used where signal stability matters. Even small damage to the inner conductor or shielding can cause signal loss, interference, or long-term reliability issues. A Coaxial Semi-Automatic Stripping Machine is built to control cutting depth and strip length with mechanical consistency.

Adjustable blades and fine-tuning mechanisms allow operators to match different cable diameters and insulation layers. Once set, the machine repeats the same stripping result across batches. This consistency helps keep conductor surfaces clean and intact, which supports later crimping or soldering steps without rework.

Balancing Speed and Control on the Production Floor

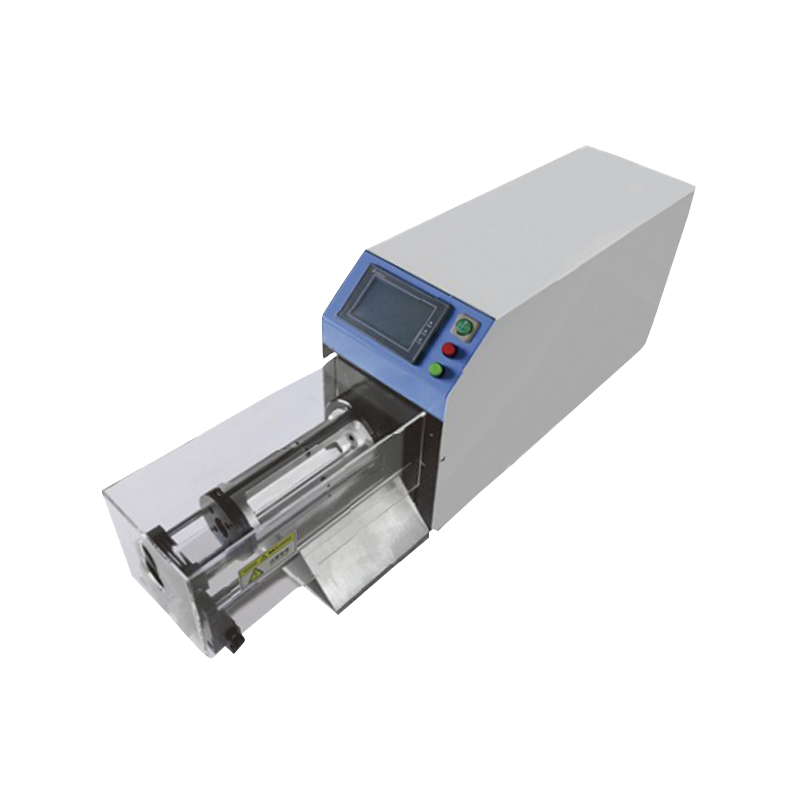

Many factories do not need a fully automated line running unattended. What they need is steady output with human oversight. A semi-automatic stripping process allows operators to load and unload cables easily while the machine handles the cutting motion.

Compared with manual tools, output becomes more predictable. Compared with fully automated units, setup time stays manageable. A Coaxial Semi-Automatic Stripping Machine supports medium to high volume work without forcing complex programming or frequent downtime.

Adapting to Different Cable Types and Sizes

Production seldom stays fixed on one cable specification forever. New projects bring new jacket materials, shielding structures, and conductor sizes. A well-designed stripping machine supports these changes through mechanical adjustment rather than part replacement.

The Coaxial Stripping Machine Series is developed with versatility in mind. Operators can adjust stripping length, blade position, and feed depth to match various coaxial cable designs. This flexibility reduces the need for multiple machines on the floor and allows faster response when orders change.

Reducing Cable Waste and Rework

Damaged cables do not just increase scrap. They slow production, affect delivery schedules, and increase inspection workload. Consistent stripping quality helps stabilize the entire assembly process.

By removing only the required layers and lengths, a Coaxial Semi-Automatic Stripping Machine helps keep material usage under control. Clean cuts reduce the chance of re-stripping or manual correction, which supports a smoother workflow between stations.

Operator Experience and Daily Use

Machines that are difficult to operate often end up underused. Clear adjustment points, simple controls, and visible stripping action make training easier. Semi-automatic machines allow operators to feel involved without needing great programming skills.

Foot pedals or hand triggers provide direct control over each cycle, which helps operators react quickly if cable specifications change during a shift. This balance between automation and manual input fits well into many factory environments.

EN

EN  English

English русский

русский Español

Español عربى

عربى