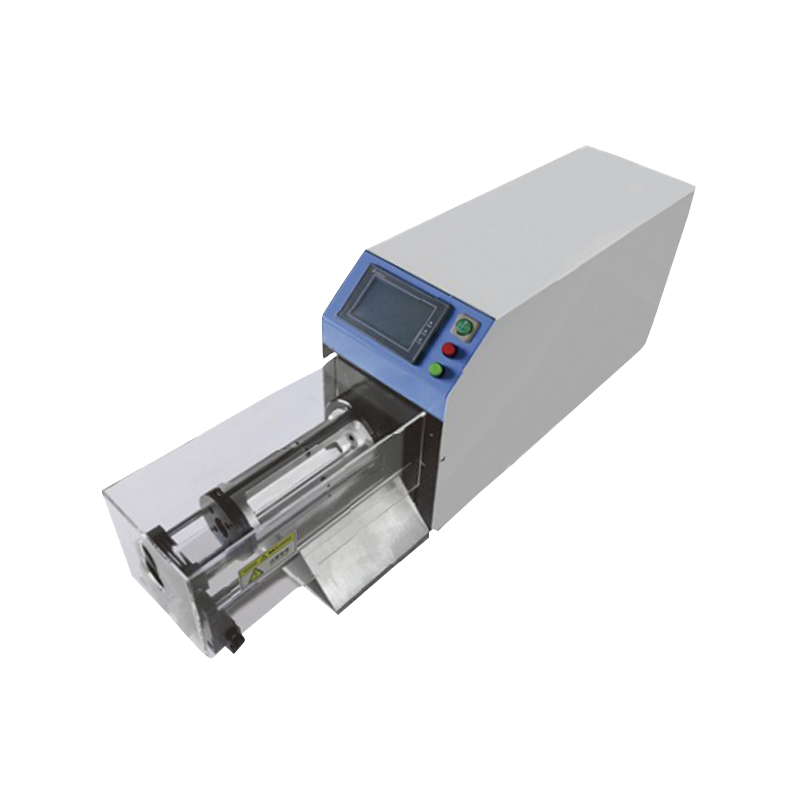

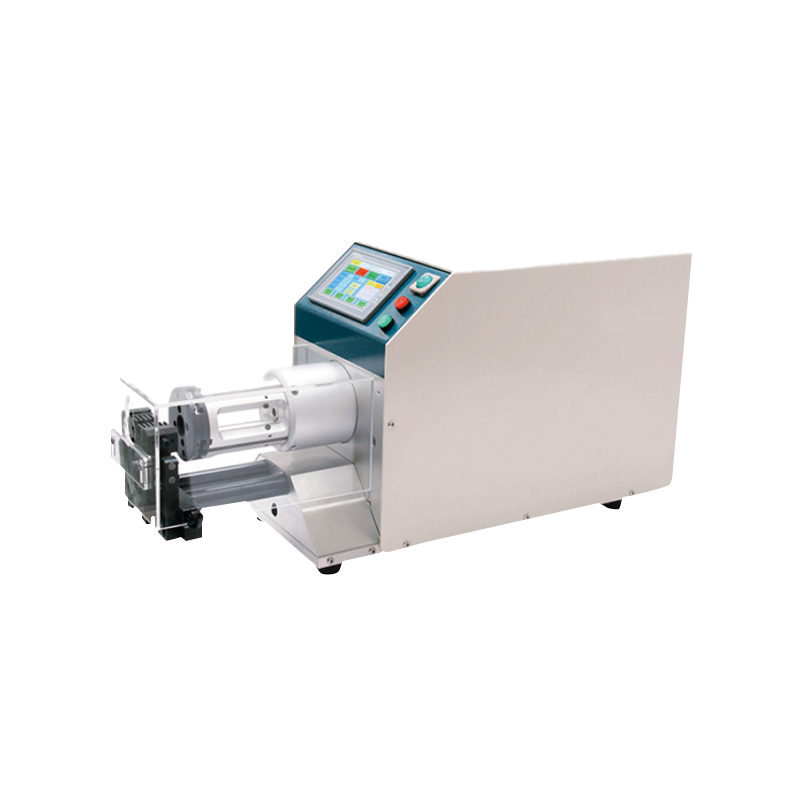

Is A Coaxial Semi-Automatic Stripping Machine Right For Your Cable Line?

A Coaxial Semi-Automatic Stripping Machine draws attention from industries working with coaxial cables because accuracy, efficiency, and smooth adjustability matter in every production run. Buyers often want to understand what this type of machine can actually bring to a cable-processing line and how Coaxial Semi-Automatic Stripping Machine Manufacturers refine their engineering to support stable output.

1. How does precision affect coaxial cable processing?

Coaxial cables require controlled stripping, especially when both the outer jacket and inner insulation must be removed without harming the conductor. A Coaxial Semi-Automatic Stripping Machine supports this need with precise cutting mechanisms that adjust according to cable size and insulation thickness. Users handling communication lines, RF cables, or sensor wiring depend on this level of precision because even small scratches on the conductor can affect transmission quality or introduce signal loss.

The semi-automatic structure also gives operators a sense of control. Instead of relying entirely on a fully automated sequence, they can verify positioning, adjust stripping depth, and maintain consistency across batches. This is valuable for workshops working with different coaxial models throughout the day.

2. What performance advantages are users usually looking for?

Speed is a priority for many buyers, especially in telecom and electronics assembly. A Coaxial Semi-Automatic Stripping Machine supports rapid processing while keeping the stripping quality stable. Automated cutting cycles shorten handling time for each piece, which helps maintain steady throughput during periods of heavy demand.

Users also pay attention to how the machine handles multiple stripping layers. Coaxial cables typically involve several materials—outer jacket, shield, filler, dielectric, and inner conductor. A machine capable of managing these layers with clean transitions reduces rework and helps keep production lines predictable.

3. Why does versatility matter when selecting a stripping machine?

Many businesses appreciate equipment that adapts to different cable sizes rather than being restricted to a single specification. Coaxial Semi-Automatic Stripping Machine Manufacturers design adjustable platforms so operators can set parameters for various cable types without swapping machines. This adaptability is useful for companies supplying diverse industries such as aerospace, automotive electronics, instrumentation, and consumer electronics.

Versatility also reduces the amount of operator training needed. When a single machine handles a broad range of cables, technicians spend less time learning multiple systems and more time focusing on consistent production.

4. What do buyers expect from capable Coaxial Semi-Automatic Stripping Machine Manufacturers?

Customers want suppliers who understand real production challenges instead of offering only basic specifications. Stable components, clear adjustment settings, and smooth cutting performance are common expectations. Manufacturers who build machines with well-aligned blades, dependable step controls, and intuitive interfaces help operators avoid unnecessary downtime.

Environmental considerations are now a growing interest as well. Energy-efficient designs and less insulation waste during stripping appeal to companies that want equipment capable of supporting cleaner operations.

A Coaxial Semi-Automatic Stripping Machine responds to real production needs by combining precision, stable processing, and adjustable features suitable for coaxial cable work. When comparing options from different Coaxial Semi-Automatic Stripping Machine Manufacturers, users often explore how each design supports accuracy, throughput, and long-term reliability. With careful selection, this type of machine becomes a practical addition to cable-processing lines that require dependable performance and smooth day-to-day operation.

EN

EN  English

English русский

русский Español

Español عربى

عربى