Zhejiang Wending Electromechanical Technology Co. Ltd.

Zhejiang Yueqing Wending Mechanical and Electrical Co., Ltd. was established in 2014 with a more than 5,000 square meters factory area. It consists of an R&D department, purchasing department, sales department, quality department, production department, e-commerce department, mold R&D center, and other departments, and is continuously used The precision, stability, and reliability of the advanced production equipment products rank among in the country.

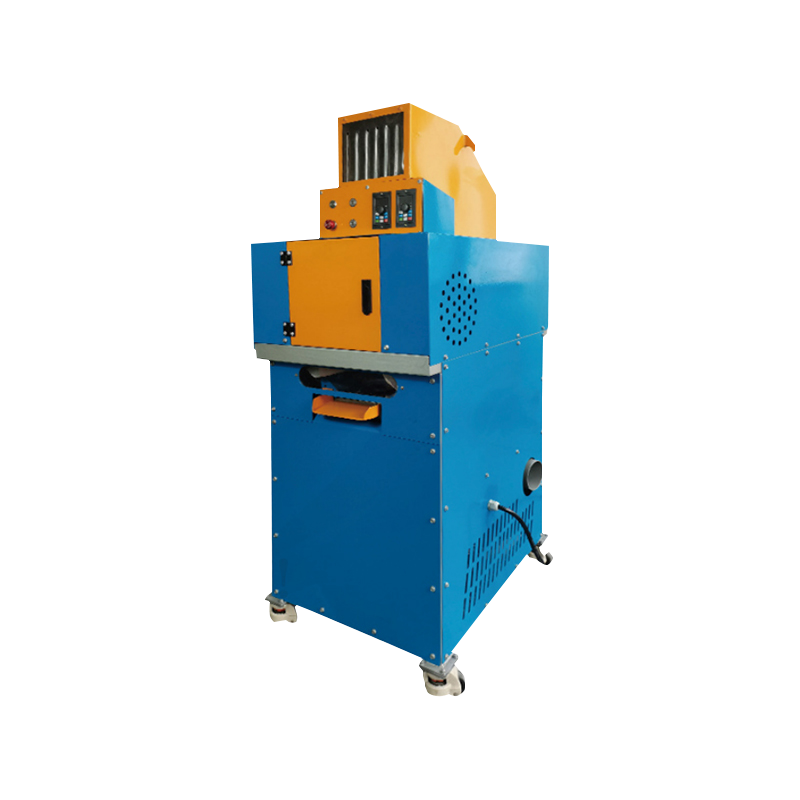

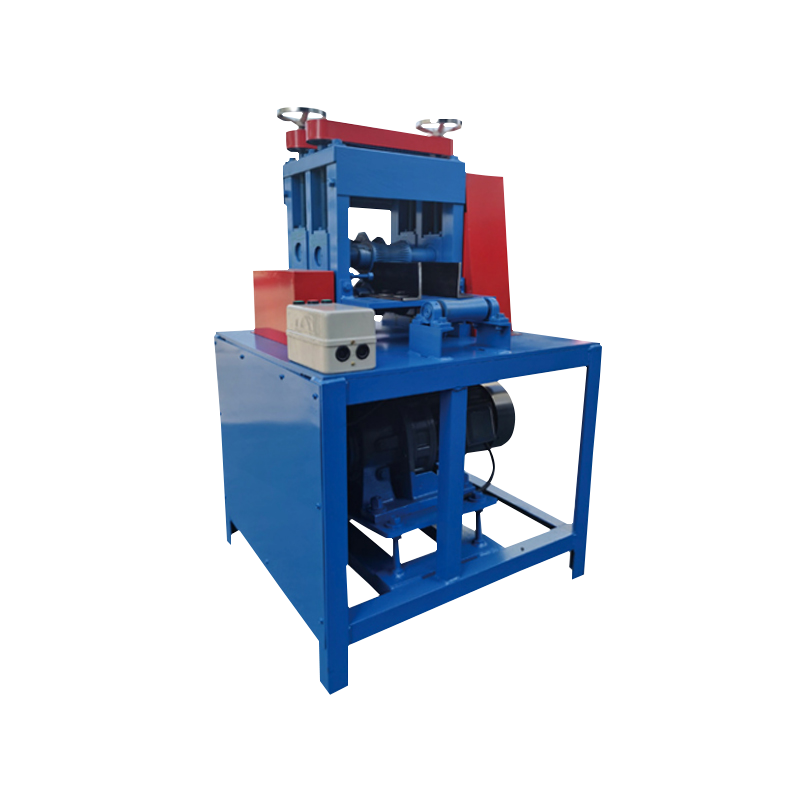

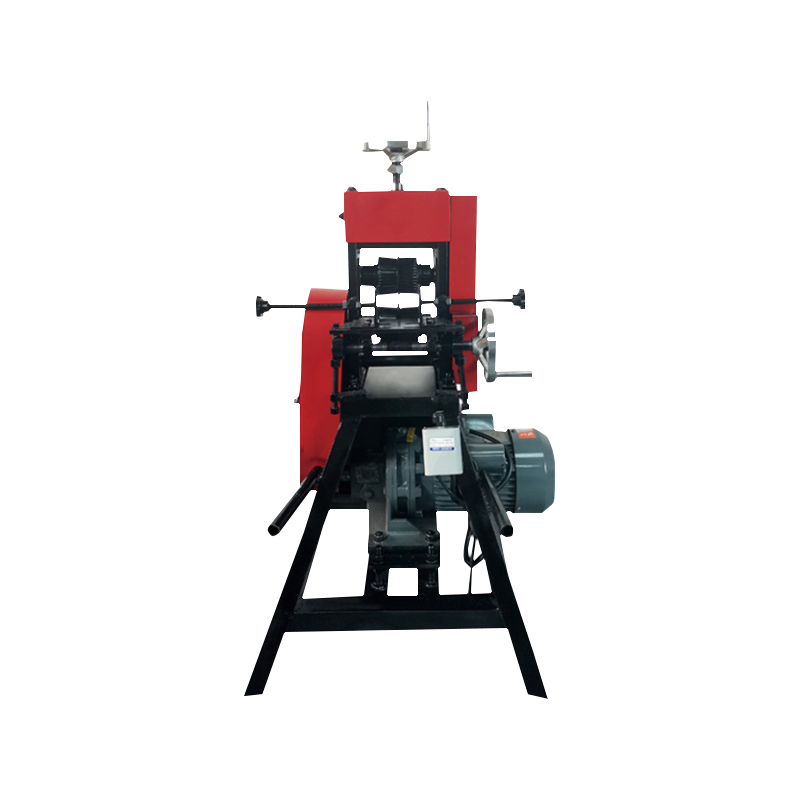

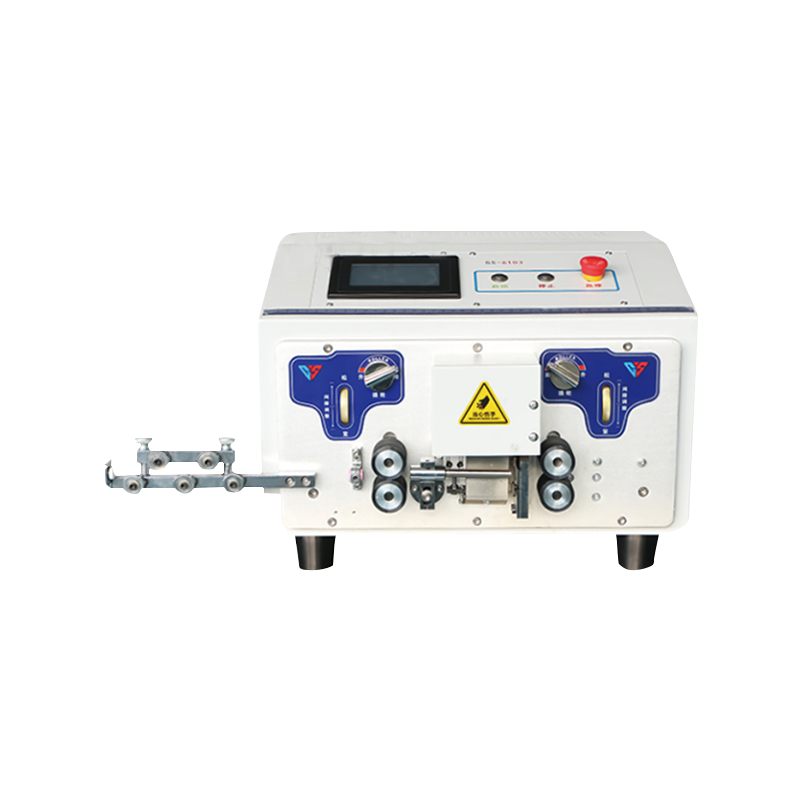

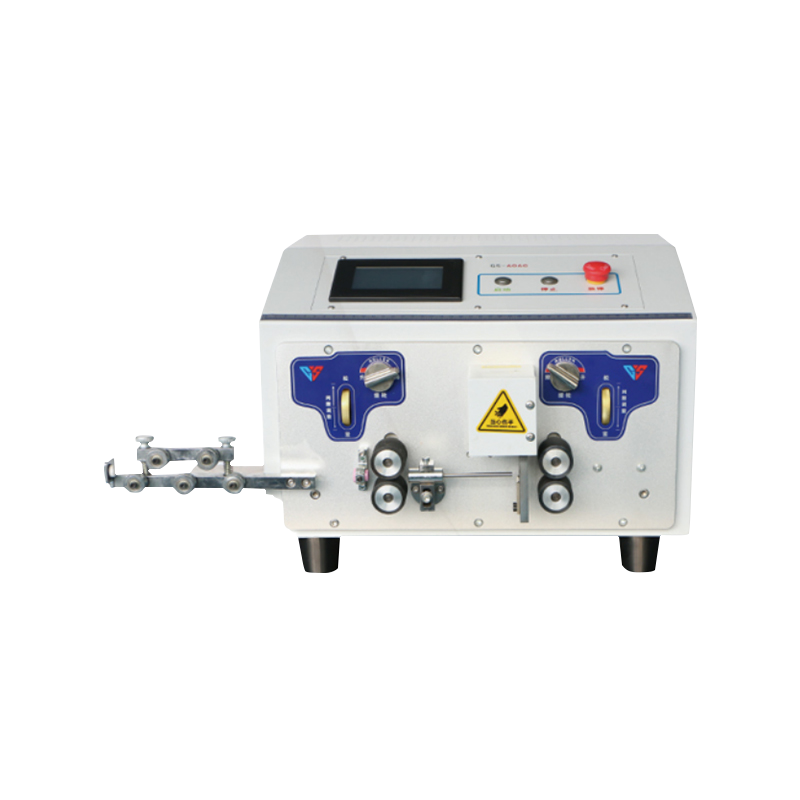

We are a professional

OEM Navy Blue Hand Stripping Machine company, and have many years of experience in

custom Navy Blue Hand Stripping Machine. It has a variety of domestic and foreign patents and CE certifications and is still developing more high-end products. Provide customers with high quality products with advanced technology.

EN

EN  English

English русский

русский Español

Español عربى

عربى